Ahead in — INNOVATION

Ahead in — INNOVATION

Your project

Our — Challenge

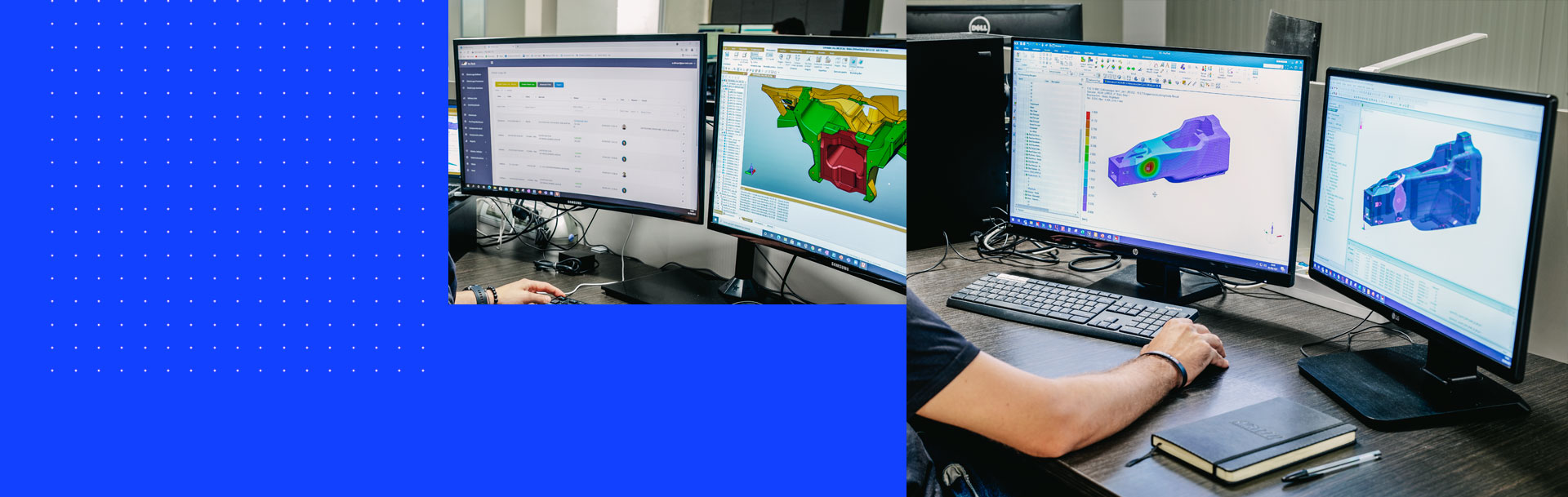

The passion for lightweight design is the driving force behind the ARS TECH team. In the Technical Area, engineers specialized in component and equipment design, mechanical draftsmen, CNC machine programmers, and project managers are dedicated to ensuring that every project is executed with the utmost punctuality, precision, and professionalism.

With a dedicated project manager for each project, every client’s challenge becomes ARS TECH’s challenge as well, ensuring a total commitment to achieving the defined objectives.

With a dedicated project manager for each project, every client’s challenge becomes ARS TECH’s challenge as well, ensuring a total commitment to achieving the defined objectives.

Our heart —

Research and Development

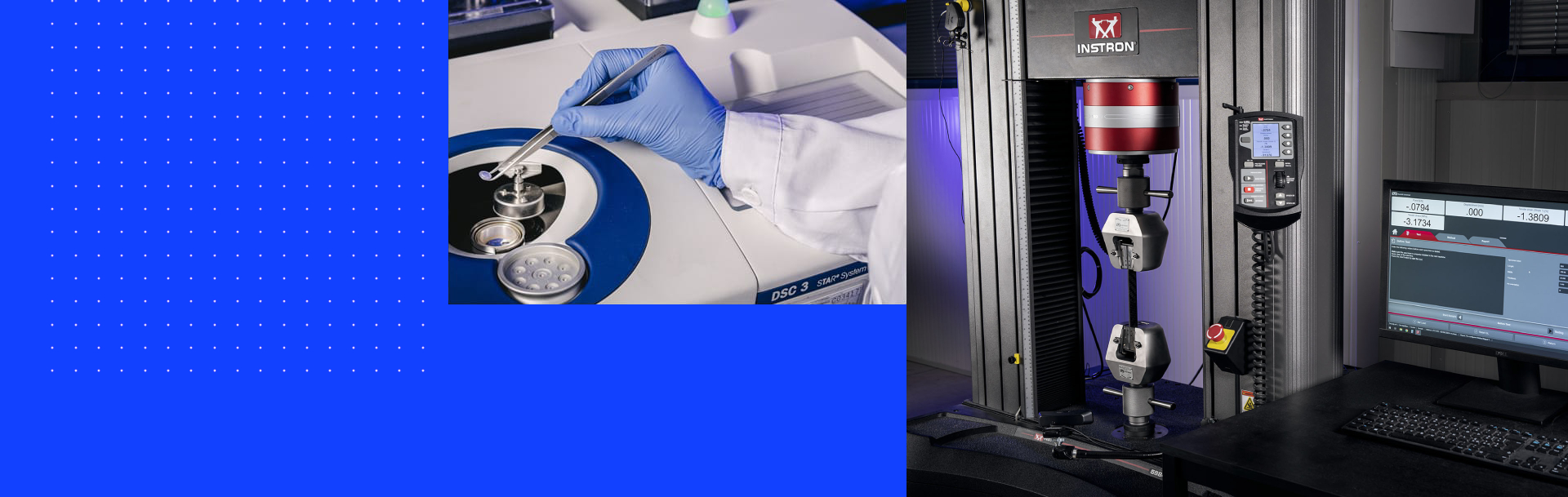

Research and Development (R&D) is the heart of ARS TECH; it’s where the most significant innovations originate, positioning the company as a leader in the world of automotive composites. The successes achieved so far by R&D, coupled with the innovative technologies developed, enable the combination of high performance, efficiency, productivity, and product quality control.

The R&D team consists of a highly specialized group of engineers with expertise in composite materials, chemistry, and mechatronics. These professionals use highly sophisticated equipment to develop optimal processes and materials. Their ongoing commitment is focused on pushing the company’s performance to the forefront of the industry.

Furthermore, ARS TECH cultivates collaborations with Italian and foreign universities to further enrich its research and development activities, maintaining an innovative approach to innovation.

-DSC (Differential Scanning Calorimeter)

-Rheometer

-Instron Dynamometer with a 150kN load cell

-Thermal Camera

-Homologation test structure for FIA and ACO

-Microscope

-DMA (Dynamic Mechanical Analysis)

The R&D team consists of a highly specialized group of engineers with expertise in composite materials, chemistry, and mechatronics. These professionals use highly sophisticated equipment to develop optimal processes and materials. Their ongoing commitment is focused on pushing the company’s performance to the forefront of the industry.

Furthermore, ARS TECH cultivates collaborations with Italian and foreign universities to further enrich its research and development activities, maintaining an innovative approach to innovation.

-DSC (Differential Scanning Calorimeter)

-Rheometer

-Instron Dynamometer with a 150kN load cell

-Thermal Camera

-Homologation test structure for FIA and ACO

-Microscope

-DMA (Dynamic Mechanical Analysis)

Our methodology —

Test and Control

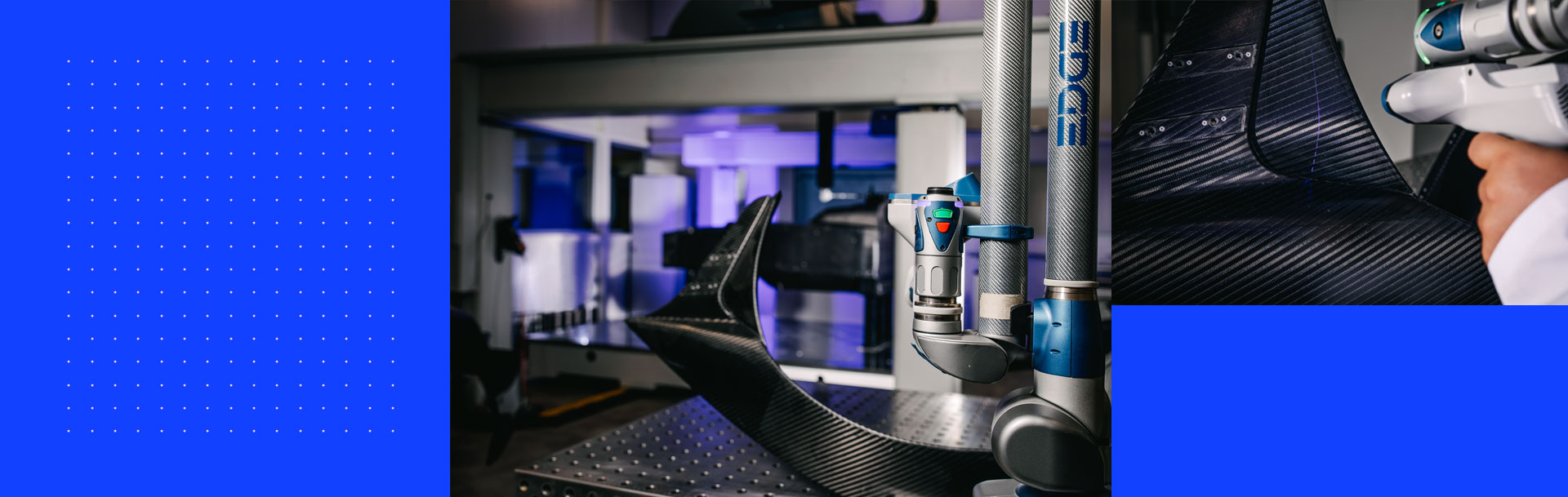

Quality is the foundation of the entire production process at ARS TECH, which is why a rigorous inspection plan is implemented at every stage of product creation: from material sourcing, through tooling, to the release of the final product via homologation tests. Furthermore, all structural components are 100% inspected both during processing and at the final inspection stage, utilizing a Coordinate Measuring Machine (DEA CMM) to ensure absolute precision.

Equipments, Systems, Tools for inspections: DEA (Coordinate Measuring Machine), Faro Arm, Faro Tracer, Thermal Camera, Arc Lights.

Equipments, Systems, Tools for inspections: DEA (Coordinate Measuring Machine), Faro Arm, Faro Tracer, Thermal Camera, Arc Lights.

Keep in —

TOUCH

Do you want to request more information?

We are ready to respond to your inquiries.

We are ready to respond to your inquiries.